Welcome to Stephenson Engineering

We take your high-integrity machined components, fabrications and structures from paper to paint within our facility…

Over the past 60 years, we’ve developed a broad and loyal customer base, through offering general engineering services and specialist support to a vast range of customers across various industries.

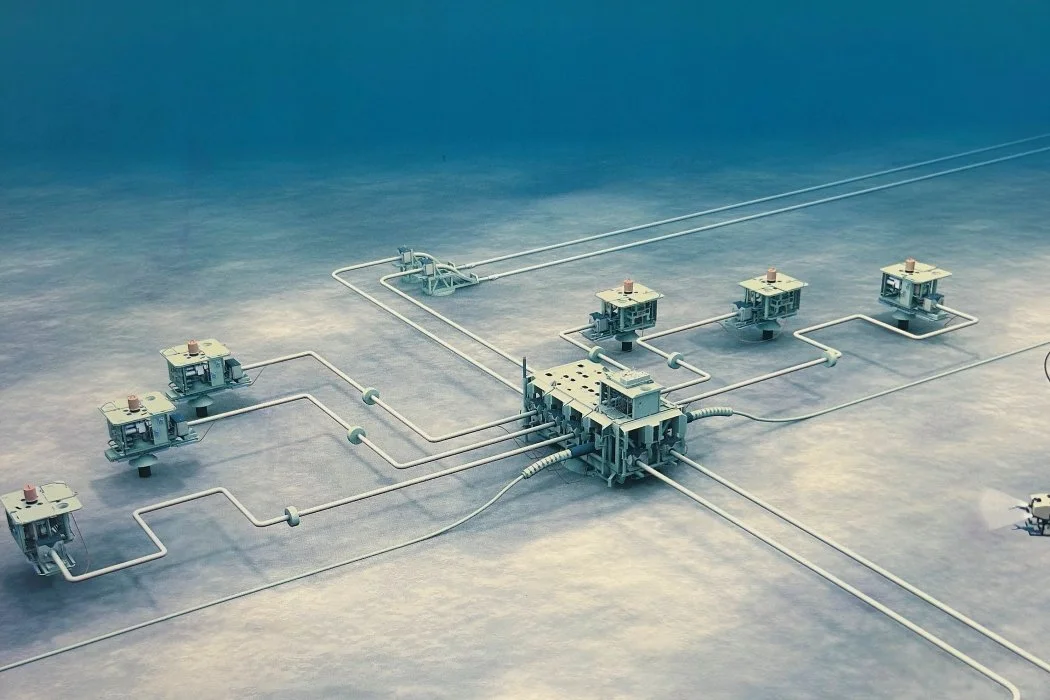

Specialist in complex CNC machined components and welded fabrications up to 35 tonnes

Operating from a modern, purpose-built facility, Stephenson Engineering offers an integrated supply chain solution. Our multiple capabilities include; profile flame cutting, coded welding, large capacity CNC machining, NDE, proof-load testing, assembly and coating - all from the same site.

We operate one of the largest capacity sub-contract machining facilities in the UK, and with our team of professional welders, we are leaders in the manufacture of complex components and large-scale steel structures.

Multi-capability manufacturing service

Our innovative turnkey service provides the following benefits:

Combining separate specialist services promotes manufacturing efficiency.

Class leading expertise, knowledge and capability delivered by all departments.

Integrating all manufacturing processes delivers total project control over schedule and cost under a continuous quality plan.

One point of contact for seamless project management without multiple suppliers and contracts.

Operating multiple services reduces transport costs, time and unnecessary packaging.

Our Sectors